All about Sandblasting Alternatives

The 3-Minute Rule for Sandblasting And Powder Coating

Table of ContentsThe smart Trick of Sandblasting And Powder Coating That Nobody is DiscussingWhat Does Sandblasting And Powder Coating Do?How Sandblasting can Save You Time, Stress, and Money.Getting The Sandblasting Alternatives To WorkTop Guidelines Of SandblastingUnknown Facts About Sandblasting Adalah

Additionally, sand consists of a high dampness web content that can result in the premature demise of blasting devices. Sharretts Plating Business now offers abrasive blowing up among its metal finishing processes. We are also readily available to provide reputable media selection advice.The typical technique for blasting light weight aluminum surfaces is to completely dry blast, and after that brighten the surface. Hereafter, the surface can be painted or covered. This benefits bigger surfaces like a car, or a boat hull. Exterior blasting is typically performed with a pressure pot sandblaster. For smaller objects, like light weight aluminum wheels, rims, or components, a more effective method now exists.

With a slurry blast cabinet, the media and also water are blended, then blew up at the surface. Both alternatives make stripping a surface area much quicker than the old completely dry blast and gloss methodology.

Sandblasting Adalah - Questions

Conversely, the greatest disadvantage with wet blasting is that you'll need to layer the blown up surface faster than with dry blowing up. Wet blowing up removes a whole lot of the ingrained media fragments that you locate with completely dry blowing up, however paint or coating should be done quickly to remove any chances of oxidation.

If you dry blast, you may still require to brighten the surface area after the blasting is ended up. Some light weight aluminum surface areas have thinner panels than other materials. To prevent warping throughout rough blasting, start with a reasonably reduced stress, 50 to 60 PSI, as well as increase as required. For had blasting, like in an rough blast cupboard, the size of the closet as well as blast nozzle will affect just how much PSI you require to utilize.

If the air stress and results appearance great, feel cost-free to blast the remainder of the surface area taking legal action against the same conditions. Depending on what kind of light weight aluminum surfaces you will be blowing up, and also how often, there are various types of devices you need to use.

A Biased View of Sandblasting

Sandblasting is an efficient means to remove paint from a range of surfaces though it is an unpleasant and also potentially harmful work. Knowing the right applications for the technique is the crucial to obtaining the results you desire. Sandblasting makes use of an air compressor to shoot sand at a high rate toward an object.

Sandblasting can be made use of to get rid of paint from any kind of object that will hold up to the intense abrading force of sandblasting. Brick, concrete as well as metal surface areas generally fall into this group. Sandblasting can be made use of to eliminate paint from timber though it will cause matching as well as marking on the surface area of the wood. sandblasting alternatives.

If there is any type of inquiry as to whether the paint being gotten rid of could have lead in it, sandblasting sandblasting east london ought to not be utilized to eliminate it. Lead was outlawed from paint as of 1978, yet if there is a chance that the surface you're functioning with was painted in the late seventies or in the past, have the paint examined for lead before sandblasting it.

8 Simple Techniques For Sandblasting Machine

The package consists of a hopper to hold the sand, an air hose to affix it to the air compressor and an unique nozzle designed for sandblasting. The extra effective the air compressor, the stronger the spray of sand will certainly be as well as the more reliable your efforts will certainly be. A stress of 50 psi is the minimum required for sandblasting though 100 psi is better.

Whatever around need to be covered with a tarp unless you do not mind it being covered with dust. Tarps additionally enable you to gather the sand after that as well as recycle it, though you will need to pass it via a fine filter to eliminate any kind of larger particles. Begin by placing on your respirator as well as protective clothing.

Activate the air compressor and wait for it to construct up pressure. Hold the nozzle concerning 12 inches from the painted surface area, press the trigger for the sand ahead out and make use of a to and fro movement to get rid of the paint in broad, even strokes. Various types of paint vary in just how easily they can be gotten rid of and also different surface areas vary in exactly how conveniently they Clicking Here can be harmed by sandblasting.

Sandblasting Aluminum Things To Know Before You Get This

There is no unique key to sandblasting success, various other than perhaps your patience with what is a very messy process. If at any point you feel like you're in over your head, don't be reluctant to choose up the phone and also call an expert.

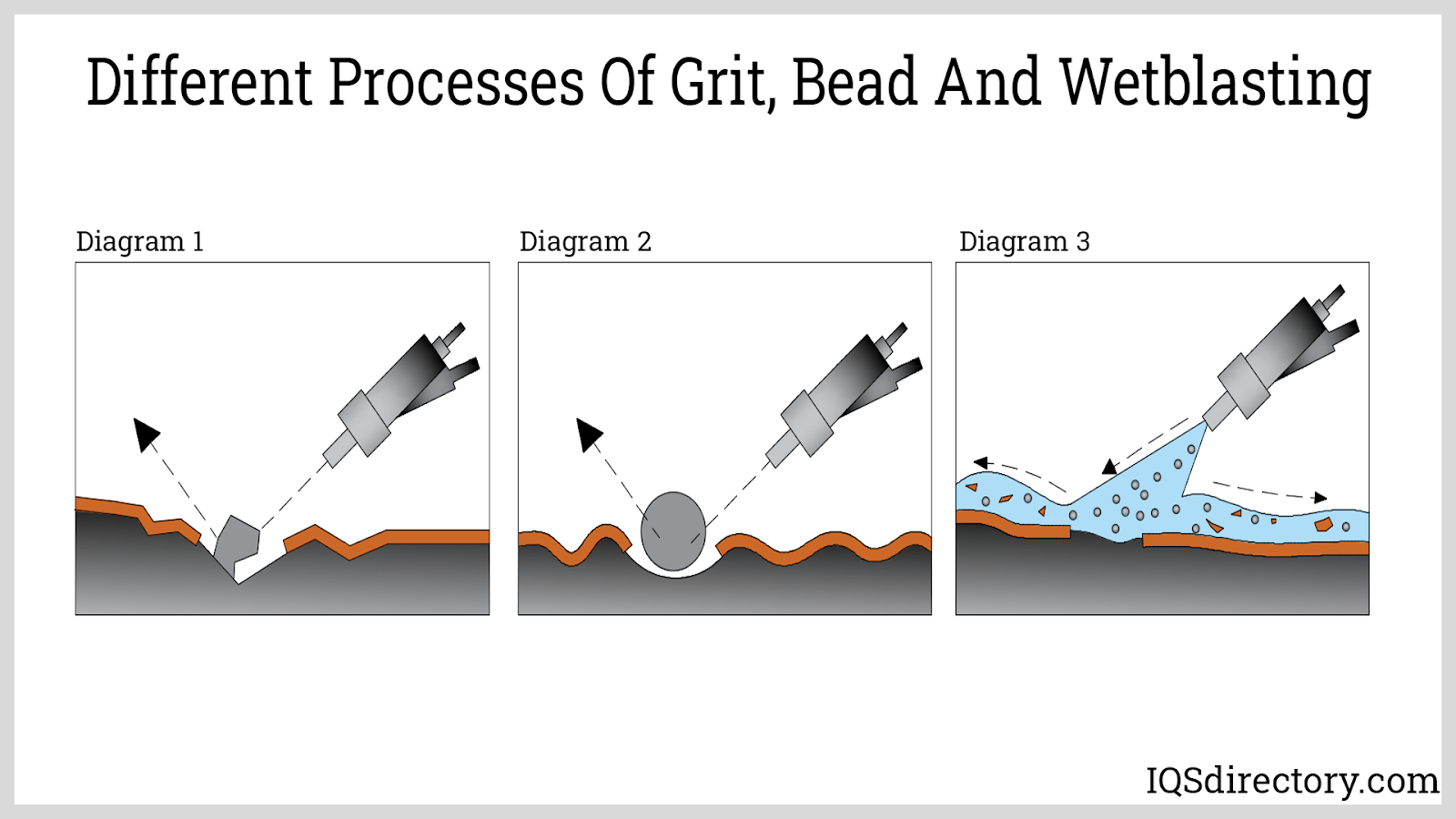

Wet Sand blowing up vs Dry Sandblasting has seen more interest over the previous 8 years and also a significant change has actually begun to take place in the unpleasant blowing up room as a result of it. This change is relocating from completely dry blowing sandblasting booth for sale up to damp blowing up. Some have commonly heard it called damp sand blowing up or dry sand blasting. sandblasting at home.

In the following paragraph we will dive deeper into the process degree distinctions as well as what you can expect to leave a wet blowing up equipment if you determine to take the following action in making the button.

Rumored Buzz on Sandblasting Alternatives